How to treat your outdoor reclaimed timbers (and other wood too!)

AU natural, new wood siding. Board & batten style

Natural wood is a favourite cladding, porch and structural material in rural Ontario.

But it comes with the big questions of maintenance and decay.

This article will discuss exterior wood and alternative options for those who don’t want to risk maintenance.

Nature does not design materials to last forever; decay is as important as life on earth.

Water is the biggest enemy of wood. Decay happens when wood is allowed to remain wet and damp. But wood has a large capacity to dry out, so if you give wood the opportunity to wet (which is nearly impossible to avoid) but also dry, your wood can last a long time.

At VELD Architect, we attempt to work with nature rather than try to beat it (because we know who always wins!) So we treat exterior wood that is always natural to operate, and wood can use its natural tendencies to wet & dry. So, any product that is designed to “seal” the wood and keep all moisture out is a product that will fail (as nature always wins) and that you will have to maintain and reapply.

Here are 4 products and approaches for exterior woods:

1. Sansin

Sansin is a product that is designed to let the wood breathe but still repel water.

Sansin exterior products are readily available at your local paint store. They are water-based, which allows the water to carry the oils deeper into the wood, allowing it to repel water over a longer time. We have seen this product not fade and maintain wood decks better over longer periods of time.

2. Lifetime Preservative

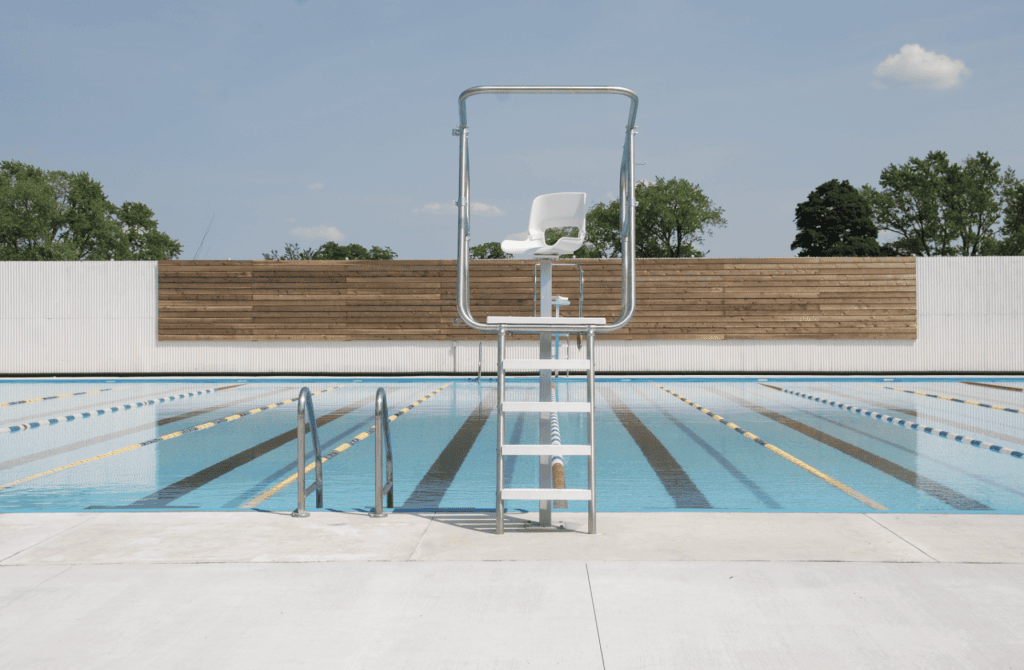

Fencing at Harry Class pool in Kitchener using lifetime preservative on cedar

A natural product designed to grey your wood quickly and evenly so that it naturally protects itself. Our understanding is that it petrifies the exterior of the wood, allowing the wood to naturally protect itself. The downside is that you only get one colour choice, and that’s nature’s greyed wood.

https://www.valhalco.com/why-use-lifetime-wood-stain.php

3. Boat soap

It is a handmade mixture of linseed oil and paint thinner. We got this recipe from a veteran timber framer as his go-to wood treatment.

The name boat soap comes from the fact that it is used on boat hulls. A highly-water-susceptible location for wood to be. So, it’s got some grit. The recipe/method is as follows:

- One part double-boiled linseed oil (sometimes referred to as "treated") to two parts solvent or paint thinner.

My personal preference is for Varsol as it has fewer VOC and aroma issues than most - especially important in interior applications. That's it: Boat Soap. You can vary the overall ratio to suit your needs and working style - the solvent is simply there to thin the oil enough to carry into the wood.

4. No coatings

We know nature is good at her job, so we often don’t spec anything. Barns around the countryside have no coatings! But it takes time. 5-10 years to go a nice deep grey.

But you get what you get, and you don’t get upset! Uneven greying from the sun and shading!

| Sansin | Lifetime Preservative | Boat Soap | No Coating (Nature) | |

| Colour Selection | Hundreds of choices, solid or transparent | One Option Nature’s grey | One Option Nature’s grey | One Option Nature’s grey |

| Availability | Benjamin Moore stores | Online | Hardware | N/A |

| Approx. Cost per sq2 | $0.10-0.25 | Re-apply every # of years | $0.25 | $0 |

| Re-apply every # of yrs | 5-8 years | Never | 3 years | Never |

| Low VOC | yes | yes | yes | yes |

| Environmental Friendly | Moderate | yes | Moderate | yes |

Comparison table of different wood products

Tips:

- For achieving an even weathered wood look, use a coloured/tinted coating

- For walls that are shaded, under porch roofs, or even under eaves, they will not weather at the same rate or evenly, so you can use a colour or Lifetime Preservative to help it more evenly grey.

- Coat all cut ends of wood with some water protection. This includes siding boards, timber bases, and caps. Where it works aesthetically, try to cover ends and horizontal surfaces that collect and hold water with flashing. You can also slope-cut top surfaces to completely avoid water collection.

- For mortise and tenon joints & pockets, try to reshape them to slope and drain water out. Clean any debris from the pockets.

- Make sure the wood is dry and clean.

- Pressure wash the wood with light pressure to remove debris, moss, old coatings, etc. Don’t use high pressure on older wood, as it will take the natural patina (colour) off and the debris.

Products to avoid:

- Polyurethane

- Varathane

- Urethane

These three products attempt to form a surface film that bonds to the wood. This film prevents the wood from drying if it gets wet. If the film stays intact, is applied completely to every nook and cranny, and doesn’t crack over its life time it would in theory keep all the water out. But those are BIG ifs, and we know that this doesn’t happen. Mother nature always wins, and the surface film breakdowns allowing water to get under them and into the wood. However, now the water does not have an easy way to dry out, thus causing rot.

Alternatives to wood:

If the wood look is what you want, but you really don’t want the maintenance, then consider some of these products:

Maibec Board and batten-style cladding

1. Maibec wood siding

This is a wood siding that has been factory sealed with paint or stain. It comes with a 15-year warranty on the solid colours and an 8-year warranty on the semi-transparent colours. The semi-transparent colours are generally the more wood-like. This product has a medium cost premium and is very important that the installer follow the manufacturer’s directions when installing and seals any cuts chips and damage while installing.

Vicwest “wood” siding. Cedar colour

2. Aluminum

Super high durable fake wood siding. It comes in a number of colours and it very sharp. As it is aluminum it is high on the expense scale, but it will last a long time and can be used in places of high moisture damage potential such as soffits.

The alternative to Aluminum is Steel and Vicwest and other companies are now producing a lower cost fake wood siding material. Steel provides all the advantages of maintenance free and has a decent colour range. And is semi-convincing from a distance that you are using wood. The downside is it only comes in limited profile styles.

3. Hardi-board or cement board

We sometimes recommend this. It is a extremely durable material, but it can be costly to install and is not as convincing as the steel alternative.

4.Charred Wood (Shou Sugi Ban 焼 杉 板 (or Yakisugi))

We have not specifically used this yet and seen the results, but apparently the Japanese have been using this technique for hundreds of years. By burning the face of the wood, you naturally protect it from water damage. The success we have seen is in areas that are protected and not subject to high traffic. So, roofs and surfaces subject to snow and ice seem to not stand up to the damage, but protected surface can do much better.

(https://southparrylumber.ca/kindl/about_kindl/)

This is the expertise VELD architect provides to your barn conversion project.

We help you make the right decisions for your project. We don’t just pick. We educate you along the way so you know, too. Join our mailing list to continue to get information and articles like this.